Glass

Glass manufacturing is a high-temperature, energy-using industrial sector. Glass making requires raw materials such as sand and recycled glass with a combination of refining, heating and casting processes.

Industry and megatrends

The glass industry is subdivided into several sectors and each has its own specificity and manufacturing process. Generally, the glass sector consists of three operations namely, the batch house, the hot end and the cold end. The batch house handles the raw materials while the hot end handles manufacturing via furnaces, annealing ovens, and forming machines. The cold end handles the product-inspection and packaging processes. The glass melting process is the basis for all the glass sectors and it involves raw materials, energy and cutting-edge manufacturing installations.

Due to its low heat conductivity and brittleness, glass is not easy to manufacture in industrial processes. The risk of breakage has to be minimized during production as well as for subsequent use due to tensions and micro-cracks caused during the production process. The moulds used in the glass industry requires strong heat durability and high precision quality. The manufacturing of these moulds would then require expertise in casting, moulding and other secondary processes such as welding and surface coating to enhance and repair the moulds.

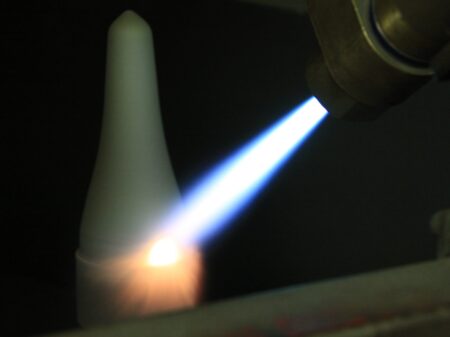

With our years of experience, Dura-Metal supported the industry with our specialized welding and surface coating technologies to provide the expertise needed. Our product range includes welding and coating equipment and consumables as well as product development on cast iron alloy and non-ferrous material (Silicon bronze). In addition, Dura-Metal plays a vital role in the joint development of parts for the various glass industry’s applications.

Some of our applications:

- Baffle

- Plungers

- Bronze mould

- Cast iron mould

- Guide ring

- Neck rings

- NNPB plungers